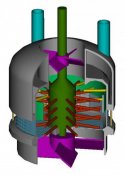

Immersion Mills

Our Patented Immersion Mill uses circulation milling technology by

rapidly pumping the slurry through the media field many more times and

more efficiently than any other mill, including basket, horizontal or

vertical mills. Remember that any mill that relies upon tank-to-tank or

same tank re-circulation is not a continuous process but a batch

process.

An Immersion Mill (a quantum improvement over traditional basket mills)

combines mixing and milling achieving maximum particle size

distribution, increasing production efficiency, and producing

extraordinary quality and profitability. Immersion milling is a

revolution in processing technology that defies comparison. Its unique

design and method of operation surpasses all other systems, enabling the

entire milling process to take place within a single water-cooled

milling chamber.